elastomeric bridge bearing Manufacturer

Unmatched in elastomeric bridge bearings, we’ve played a key role in over a thousand global projects. Trust SHUANGLIN for reliability, precision, and proven excellence!

Unmatched in elastomeric bridge bearings, we’ve played a key role in over a thousand global projects. Trust SHUANGLIN for reliability, precision, and proven excellence!

Essential in modern bridges, elastomeric bridge bearings, or elastomeric bearings, offer flexibility and stability. Including bearing pads, bridge bearings, laminated elastomeric bearings, and seismic isolators—collectively known as “bridge bearing pads.” Redefine structural support with adaptability and longevity. Elevate your projects with these engineering marvels.

- Ideal for vertical loads (<12,000 kN) and movements up to ± 250 mm

- Handles horizontal forces up to 800 kN

- Remarkable rotation capacity of up to 30 mrad

-Operates from -25°C to +50°C

- Reduces dynamic load acceleration

- Perfect as dynamic isolators in diverse structures

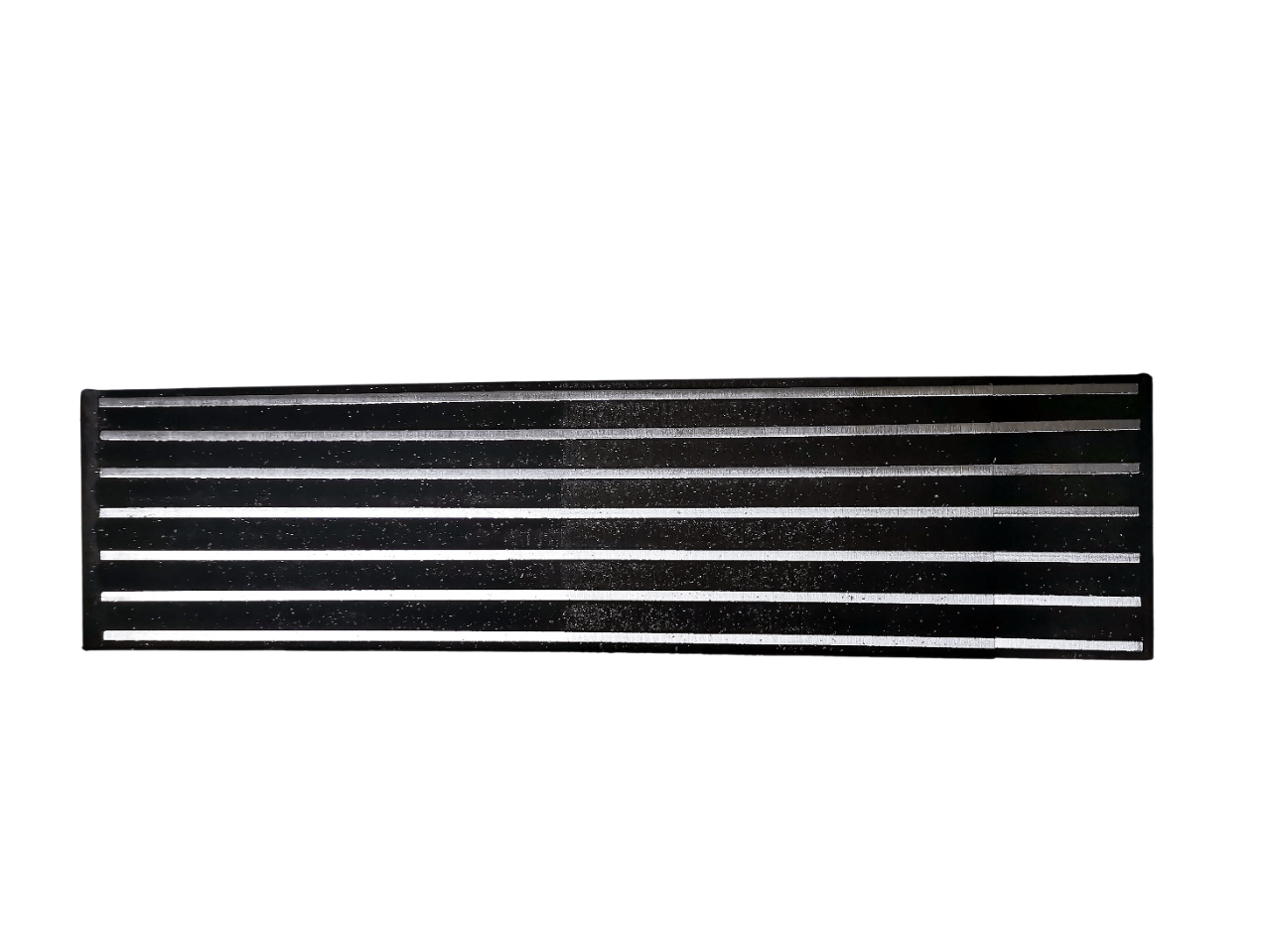

- Corrosion-protected reinforcing plates

- Rigorous rubber compound specifications

- Complies with national and international standards

- CE marked; End-to-end services available

Characterized by precision flexibility, the neoprene bearing pad ensures stability during dynamic bridge movements.

Bridge bearing laminated pads support loading up to 3000kN, ideal for spans under 30m with minimal displacement.

Production of Our Bearings According to International and Chinese Standards: ASTM D4014/D4014M. EN 1337-3:2005. ISO 22762-1:2015. GB∕T 20688.4

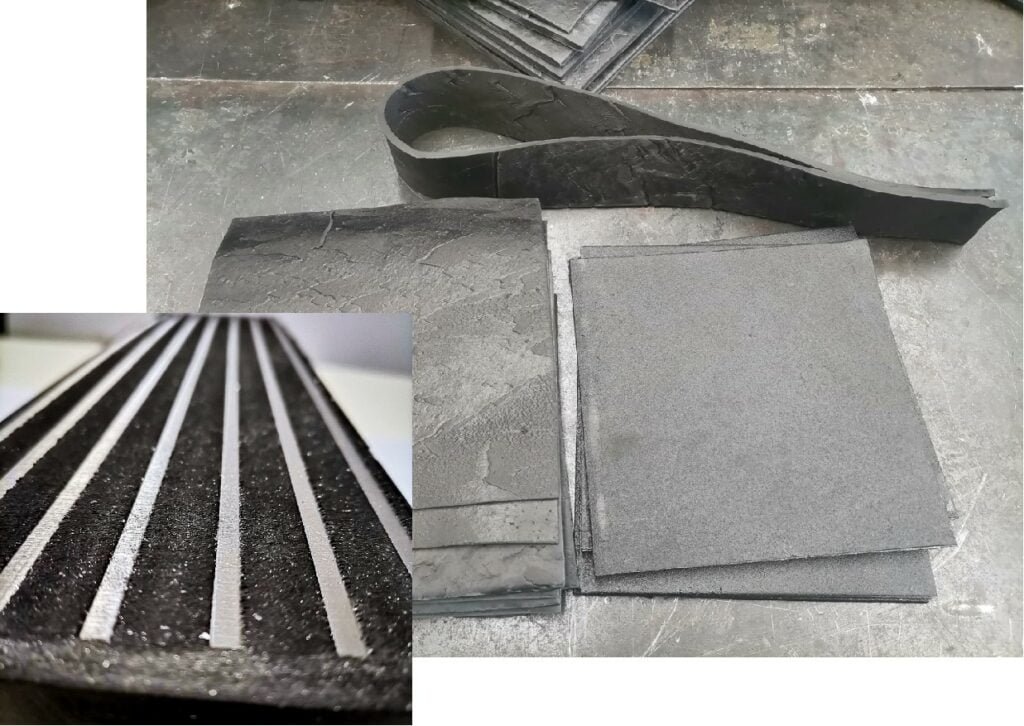

Crafted with the finest rubber materials, our elastomeric pads promise durability and optimal performance.

Meticulously processed for a flawless surface, our pads stand out with an elegant appearance and minimal imperfections.

From pre-production checks to in-process controls and final product inspections, our commitment to quality ensures consistently exceptional elastomeric bearing pads.

Emphasizing secure packaging, each product is carefully wrapped, reinforcing our dedication to delivering flawless elastomeric bearing pads.

Note: Always follow the manufacturer’s guidelines and recommended torque specifications during the installation process to ensure optimal performance and longevity of the elastomeric bearing pads.

Under normal conditions and with proper maintenance, our elastomeric bearings have a service life that can exceed 50 years.

Our bearings are engineered with a focus on fatigue life under dynamic loads. The rubber compound and steel reinforcement layers are optimized to provide durability and resilience under heavy loads.

We conduct a range of tests, including compression, shear, and fatigue tests, to validate the performance of our bearings. We also perform finite element analysis (FEA) and other simulations to ensure that our bearings meet the required specifications.

Yes, we offer bearings that are designed to meet specific seismic design requirements, including those specified in AASHTO, EN, and other international standards.

Please provide us with the details of your project, including the number of bearings required, the dimensions, and any specific design requirements, and we will provide a detailed quote.

Absolutely, our team of engineers is available to provide technical advice and, if necessary, on-site support to ensure proper installation and alignment of the bearings.

Our standard lead time is approximately 4-6 weeks from the order confirmation. For urgent needs, we may be able to expedite production subject to availability.

We provide a certificate of original, test reports, and detailed installation instructions with each shipment.