Factory-Direct Lead Rubber Bearings (LRB) for Superior Seismic Protection

Top-Quality Seismic Isolation Solutions for Bridges and Buildings

Top-Quality Seismic Isolation Solutions for Bridges and Buildings

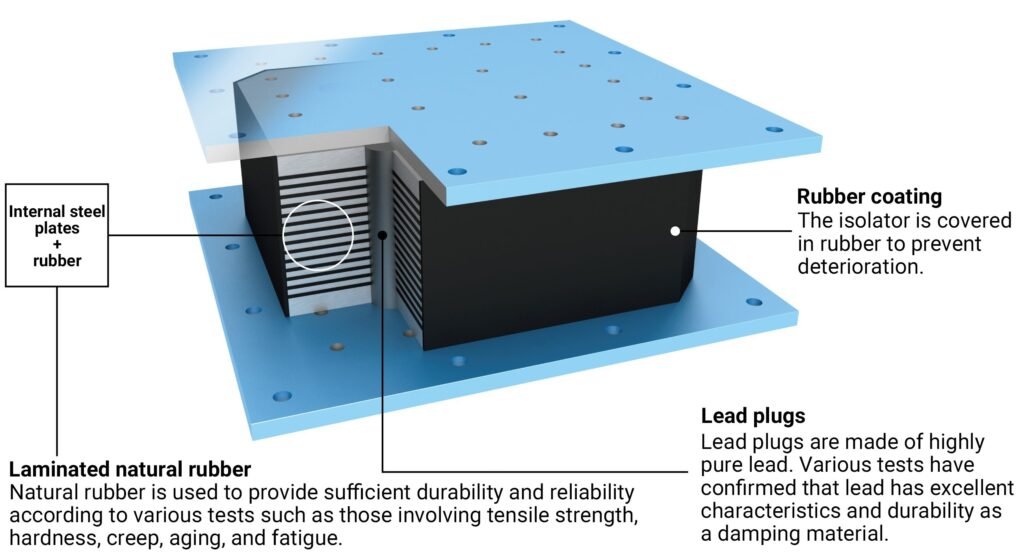

Lead Rubber Bearing (LRB), also known as lead-core rubber bearings, are advanced seismic isolation devices. Featuring multi-layer natural rubber and a central lead core, they provide exceptional flexibility, damping, and energy absorption. Ideal for bridges and buildings, LRBs reduce earthquake impacts and enhance structural stability.

Our factory offers customizable designs, ensuring compliance with national and international standards. With our expertise and top-quality materials, our LRBs are durable and ideal for both new constructions and retrofitting projects.

Laminated Bearing Pad provides seismic isolation by combining multi-layer natural rubber and a central lead core. During an earthquake, the lead core dissipates energy through plastic deformation, converting kinetic energy into heat, while the rubber layers absorb vibrations and allow horizontal movement. This dual action significantly reduces seismic forces and helps the building return to its original position post-earthquake, ensuring enhanced structural stability and integrity.

The series of Laminated Rubber Bearings bearings can be designed ad hoc to satisfy all international standards (i.e., EN 15129, AASHTO, etc.).

Lead Rubber Bearing (LRB) are vital for seismic isolation in:

1. Bridges: Highway and railroad bridges.

2. Large Infrastructure: Nuclear power plants.

3. Buildings:

– Schools, hospitals, and essential service buildings.

– Government, disaster command centers, and emergency shelters.

– Data centers, banks, and facilities with valuable or hazardous materials.

– Libraries, commercial complexes, and residences.

For lead rubber bearing, we possess top-tier technology in China, ensuring 100% compliance in testing. Our products are exported to numerous countries, meeting EN15129, EN1337, AASHTO, and ASTM standards.

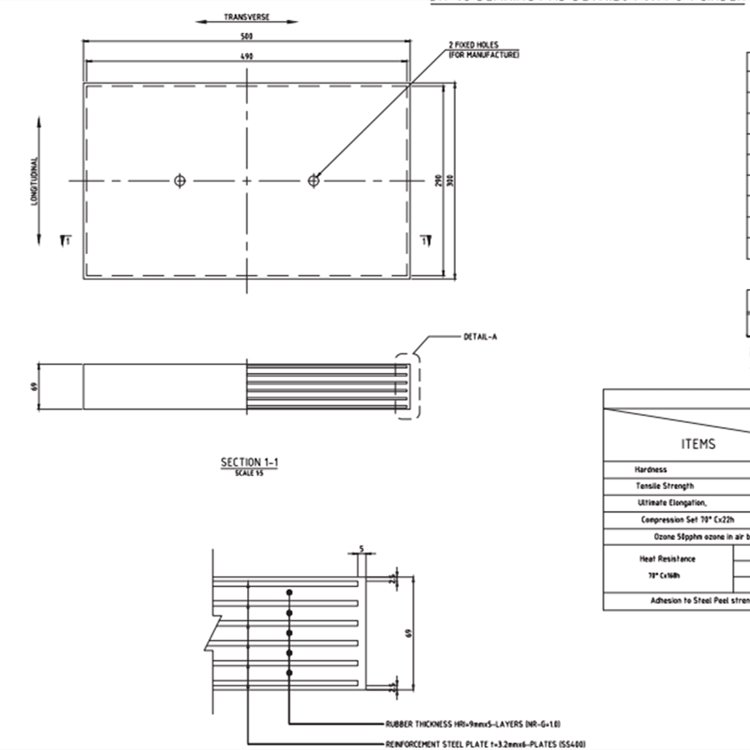

Dimension and Shape, Surface Quality, Identification and Label

Tensile Strength,Elongation at Break, Shore A Hardness, Thermal Aging, Ozone Aging, Compression Set, Low-Temperature Brittleness

Compression Strength, Compression Deformation, Shear Strength,Shear Deformation, Repeated Load Test, Horizontal Displacement Test, Rotation Test

Accessories include:

Anchor bolts, Embedded plate

Package: Pallets, wood box or customized

Our product line encompasses various sizes and types, from small deep groove ball bearings to large tapered roller bearings. You can find detailed specifications in the product catalog on our website.

Our bearings are engineered with a focus on fatigue life under dynamic loads. The rubber compound and steel reinforcement layers are optimized to provide durability and resilience under heavy loads.

We can customize the size, load capacity, rubber compound, and stiffness of our bearings to fit your project’s specific needs. Our team works with you to provide tailored solutions.

Our bearings typically last over 50 years, depending on conditions and regular maintenance.

Please provide us with the details of your project, including the number of bearings required, the dimensions, and any specific design requirements, and we will provide a detailed quote.

Absolutely, our team of engineers is available to provide technical advice and, if necessary, on-site support to ensure proper installation and alignment of the bearings.

Our standard lead time is approximately 4-6 weeks from the order confirmation. For urgent needs, we may be able to expedite production subject to availability.

We provide a certificate of original, test reports, and detailed installation instructions with each shipment.