When it comes to building bridges, one often thinks about the massive steel and concrete structures spanning across rivers and valleys. However, the true heroes ensuring these bridges stand tall and stable are often unseen—bridge bearings. These crucial components help in transferring loads and accommodating movements between the bridge superstructure and its substructure, ensuring that the bridge can endure various forces and movements. Let’s dive into the different types of bridge bearings and their roles in keeping our bridges strong and reliable.

Types of Bridge Bearings

1. Elastomeric Bearings

Design and Function: Elastomeric bearings are made from layers of rubber and steel. These bearings are highly flexible, allowing them to accommodate movements and rotations in multiple directions.

Applications: They are commonly used in short to medium-span bridges due to their ability to handle both vertical and horizontal loads effectively. Their simple design also makes them cost-effective and easy to install.

Benefits:

- Flexibility in multiple directions

- Cost-effective

- Low maintenance

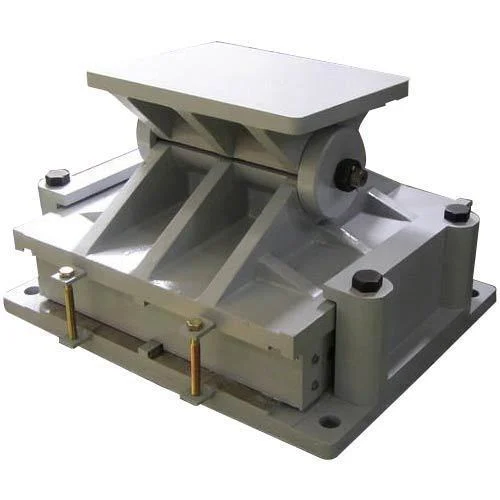

2. Pot Bearings

Design and Function: Pot bearings consist of a steel pot filled with an elastomeric disc. The disc compresses under load, allowing for rotation, while the pot confines the disc to limit horizontal movement.

Applications: These bearings are ideal for bridges with large vertical loads and minimal horizontal movements, often found in longer-span bridges.

Benefits:

- High load-carrying capacity

- Suitable for large-span bridges

- Allows rotational movement

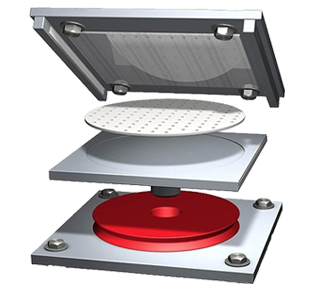

3. Disc Bearings

Design and Function: Disc bearings use a polyether urethane disc to accommodate rotation and a sliding surface to handle horizontal movements. They are similar to pot bearings but can handle more complex movements.

Applications: Disc bearings are suitable for bridges requiring high rotational capacity and are often used in areas with seismic activity.

Benefits:

- High rotational capacity

- Suitable for seismic zones

- Handles complex movements

4. Roller Bearings

Design and Function: Roller bearings consist of cylindrical rollers placed between two plates. They allow for horizontal movement while supporting vertical loads.

Applications: These bearings are typically used in bridges that require significant horizontal movement, such as expansion and contraction due to temperature changes.

Benefits:

- High horizontal movement capacity

- Durable and robust

- Easy to inspect and maintain

5. Spherical Bearings

Design and Function: Spherical bearings include a convex steel plate that allows for rotation and sliding. The bearing can accommodate large movements in multiple directions.

Applications: These bearings are used in bridges with large spans and complex movement requirements, such as cable-stayed or suspension bridges.

Benefits:

- Handles large movements in multiple directions

- Suitable for complex structures

- High load-bearing capacity

Importance of Choosing the Right Bearing

Choosing the correct type of bearing for a bridge is crucial for its stability, safety, and longevity. Factors such as the bridge’s span, the expected loads, environmental conditions, and the type of movements the bridge will experience all play a role in determining the best bearing type. Incorrect bearing selection can lead to structural failures, increased maintenance costs, and reduced lifespan of the bridge.

Conclusion: Securing the Future of Our Bridges

Understanding the different types of bridge bearings and their specific applications is essential for anyone involved in bridge design and construction. These unsung heroes of engineering ensure that our bridges can handle the stresses and strains of their environment, providing safe and reliable transportation routes. As technology advances, we can expect even more innovative bearing solutions to emerge, further enhancing the durability and functionality of our bridge infrastructure.