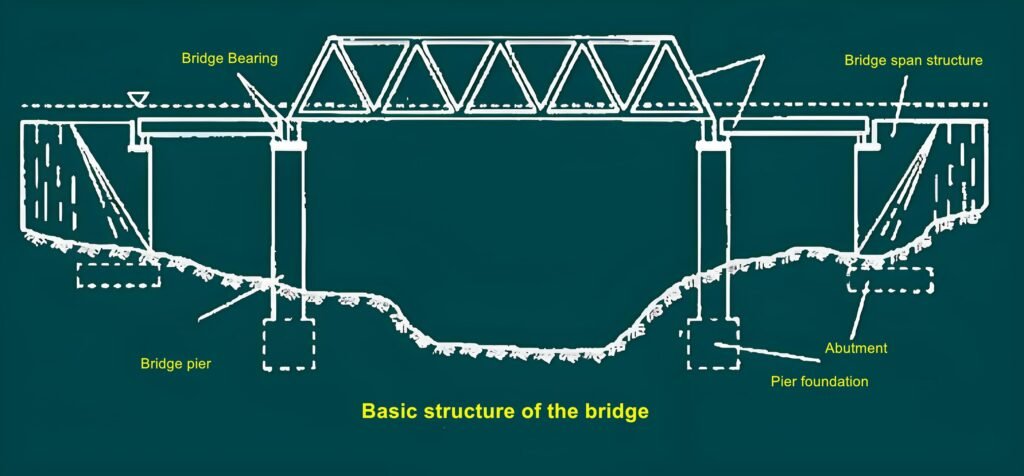

Bridges are marvels of engineering, defying gravity and connecting people and places. But these structures wouldn’t be possible without a crucial hidden component: bridge bearings. These unsung heroes silently transfer loads, accommodate movement, and ensure the bridge’s longevity and safety. This article delves into the world of bridge bearings, exploring their roles, types, selection processes, and installation methods.

The Workhorse of Bridges: Bridge Bearing Functions

Bridge bearings play a critical role in bridge functionality. They perform two primary tasks:

- Load Transfer: Bridge bearings act as the bridge’s foundation, transmitting the weight of the bridge deck (upper structure) and traffic loads (live loads) to the supporting piers (substructure). This ensures the bridge’s stability and prevents excessive stress on any single point.

- Accommodation of Movement: Bridges are not rigid structures. They experience movement due to factors like temperature fluctuations, concrete shrinkage, and live loads. Bridge bearings allow for controlled movement, preventing cracks and misalignment in the bridge structure. This flexibility is crucial for maintaining the bridge’s integrity and safety.

Bridge Bearing Classification: Fixed vs. Movable

Bridge bearings can be categorized based on their ability to accommodate movement:

- Fixed Bearings: These bearings resist horizontal movement while allowing for rotation. They are typically used on piers with low elevations or in simply supported beam bridges where one end is fixed and the other is movable.

- Movable Bearings: These bearings allow for both horizontal movement and rotation. They are commonly used in continuous beam bridges to distribute the longitudinal deformation throughout the structure. Movable bearings can be further classified as multi-directional (allowing movement in both longitudinal and horizontal directions) or one-way movable (allowing movement in only one direction).

What are the Advantages of Bridge Bearings?

Bridge bearings offer several advantages over rigid connections between the bridge deck and piers:

- Accommodate Movement: As mentioned earlier, bridge bearings allow for controlled movement due to thermal expansion, shrinkage, and seismic activity. This prevents stress concentrations and cracking in the bridge structure.

- Load Transfer and Distribution: Bridge bearings efficiently transfer loads from the bridge deck to the piers, ensuring stability and preventing overloading of any single support point.

- Reduced Maintenance: Compared to rigid connections, bridge bearings require less maintenance as they absorb vibrations and reduce wear on the bridge structure.

- Cost-Effectiveness: Bridge bearings can be a cost-effective solution compared to complex designs that need to account for all potential movements.

- Increased Lifespan: By accommodating movement and reducing stress, bridge bearings contribute to the overall longevity of the bridge structure.

How Do Bridge Bearings Work?

Bridge bearings work by utilizing various materials and design principles to achieve their specific functions. Here’s a general breakdown:

- Load Transfer: The bearing material, typically elastomeric or metallic, compresses under the weight of the bridge deck, transferring the load to the pier.

- Movement Accommodation: The bearing’s design allows for controlled movement through features like sliding surfaces, elastomeric layers, or spherical elements. These components absorb or deflect movement without compromising the bridge’s stability.

- Rotation: Certain bridge bearings allow for rotation at the connection point between the deck and pier. This can be achieved through a combination of materials and design features that permit angular movement.

The specific mechanisms of how a bridge bearing works depend on its type (fixed, movable, etc.) and material composition. However, the general principles of load transfer, movement accommodation, and rotation apply to all bridge bearings.

Material Matters: Bridge Bearing Types

Bridge bearings come in a variety of materials, each with its own advantages and applications:

- Simple Bearing: This basic type, suitable for small bridges, utilizes mortar or concrete for load transfer.

- Steel Bearing: These rely on the movement of steel parts for displacement and rotation.

- Reinforced Concrete Bearing: Used in larger bridges, these bearings offer strength and durability.

- Rubber Bearing: This popular choice provides flexibility, ease of installation, and cost-effectiveness. They are further categorized as:

- Plate Type Rubber Bearing: Offers deformation in all directions, making it suitable for various bridge types.

- Basin Type Rubber Bearing: Provides superior strength and confinement for the rubber, ideal for large span bridges.

- Special Bearings: These include vibration-damping bearings to reduce seismic impact and tension bearings for specific load scenarios.

Selecting the Right Bridge Bearing

The choice of bridge bearing depends on several factors, including:

- Bridge Type and Size: Different bridge configurations require varying degrees of movement and load capacity.

- Material Availability and Cost: Balancing performance with budget is crucial.

- Seismic Considerations: In earthquake-prone areas, bearings that absorb vibrations are preferred.

Bridge Bearing Installation: A Delicate Process

Installing bridge bearings is a critical step requiring meticulous attention to detail:

- Preparation and Inspection: The bearing is carefully inspected upon arrival, and the installation site is prepared to ensure proper alignment and dimensions.

- Positioning and Adjustment: The bearing is meticulously positioned using cranes and wedges, ensuring it meets the design specifications for elevation and alignment.

- Grouting: The gap between the bearing and the support structure is filled with high-strength mortar to provide stability and prevent future movement.

- Curing and Final Touches: After grouting, the bearing is left undisturbed to allow the mortar to cure fully. Any final adjustments are made once the mortar solidifies.

What is the difference between fixed bearing and movable bearing?

Fixed bearings and movable bearings are two main types of bridge bearings that differ in their ability to accommodate movement.

Fixed Bearings:

- Movement: Fixed bearings allow for rotation at the connection point between the bridge deck and pier, but they resist horizontal movement.

- Applications: Fixed bearings are typically used on piers with low elevations or in simply supported beam bridges where one end is fixed and the other is movable.

- Advantages:

- Provide stability and prevent horizontal displacement of the bridge deck.

- Simple design and construction.

- Lower cost compared to movable bearings.

Movable Bearings:

- Movement: Movable bearings allow for both horizontal movement and rotation at the connection point between the bridge deck and pier.

- Applications: Movable bearings are commonly used in continuous beam bridges to distribute the longitudinal deformation throughout the structure. They are also used in bridges with curved or skewed alignments.

- Advantages:

- Accommodate movement due to thermal expansion, shrinkage, and seismic activity.

- Reduce stress concentrations and cracking in the bridge structure.

- Allow for flexibility in bridge design and construction.

Choosing Between Fixed and Movable Bearings:

The choice between fixed and movable bearings depends on the specific requirements of the bridge and its environment. Factors to consider include:

- Bridge Type and Configuration: Continuous beam bridges typically require movable bearings to accommodate longitudinal movement, while simply supported beam bridges may use fixed bearings on piers with low elevations.

- Movement Expectations: The amount of expected movement due to temperature changes, shrinkage, and seismic activity should be considered when selecting the bearing type.

- Design Considerations: The overall design of the bridge and the desired flexibility of the structure may influence the choice between fixed and movable bearings.

FAQs

- Q: What happens if a bridge bearing fails?

A: Bridge bearing failure can have serious consequences. It can lead to misalignment, cracking, and even collapse of the bridge structure. Regular inspections and maintenance are crucial to detect and address bearing issues before they escalate.

- Q: How long do bridge bearings typically last?

A: The lifespan of a bridge bearing depends on various factors like material, traffic volume, and environmental conditions. However, with proper maintenance, bridge bearings can last for several decades.

- Q: Can bridge bearings be replaced?

A: Yes, bridge bearings can be replaced. It is a crucial part of bridge maintenance to ensure the structure’s integrity and safety. The replacement process is complex and requires specialized expertise and equipment.

- Q: What are the different types of bridge bearings available?

A: Bridge bearings come in various types, each with its own advantages and applications. Some common types include fixed bearings, movable bearings (multi-directional or one-way), simple bearings, steel bearings, reinforced concrete bearings, and rubber bearings (plate type or basin type).

- Q: What factors are considered when selecting a bridge bearing?

A: The choice of bridge bearing depends on several factors, including the bridge type and size, material availability and cost, seismic considerations, and the amount of expected movement due to various factors.

Conclusion

Bridge bearings, whether fixed or movable, play a crucial role in the functionality and longevity of bridges. By understanding their differences and selecting the appropriate type for each application, engineers can ensure that bridges remain stable, safe, and resilient for years to come.