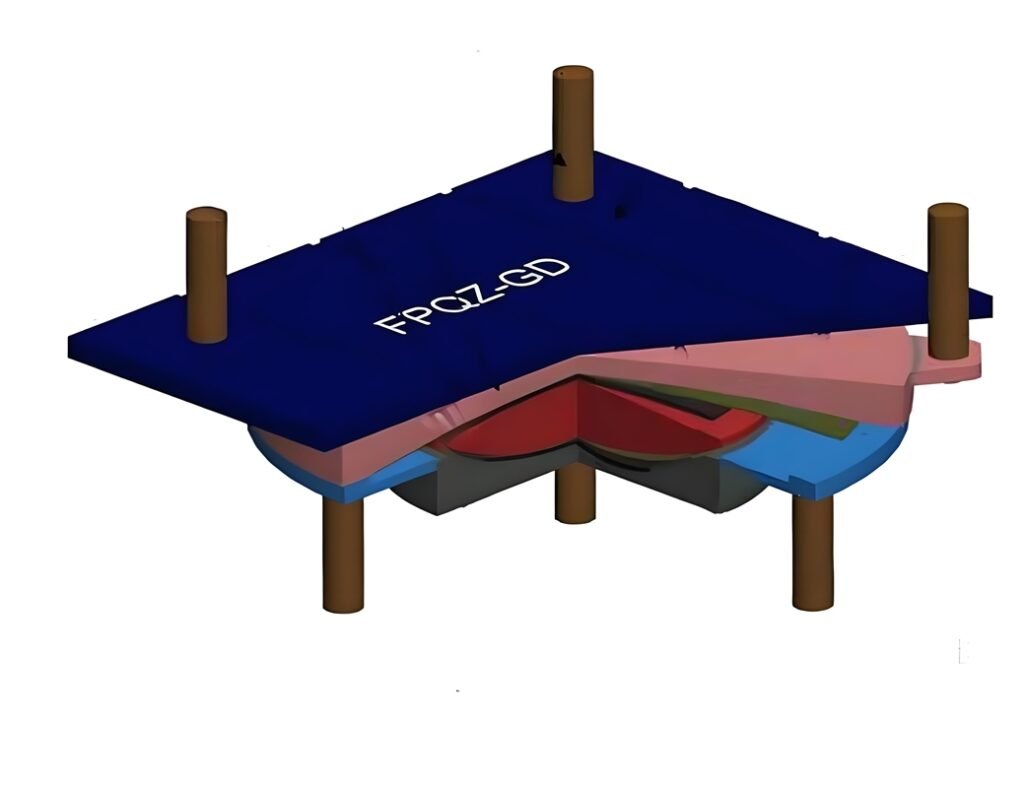

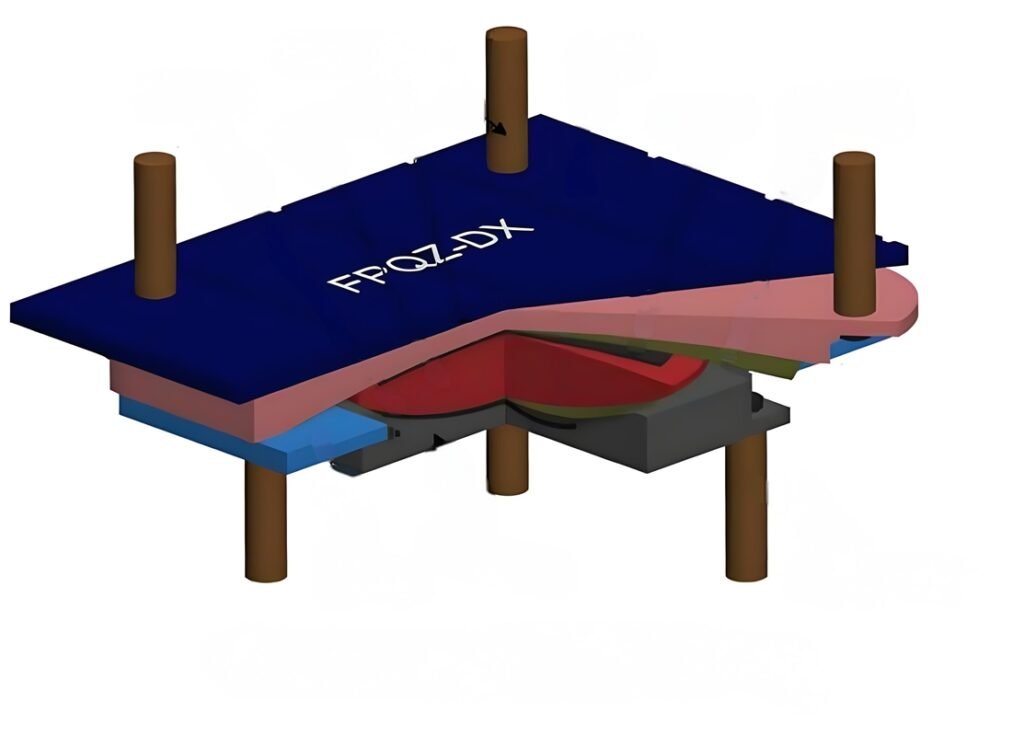

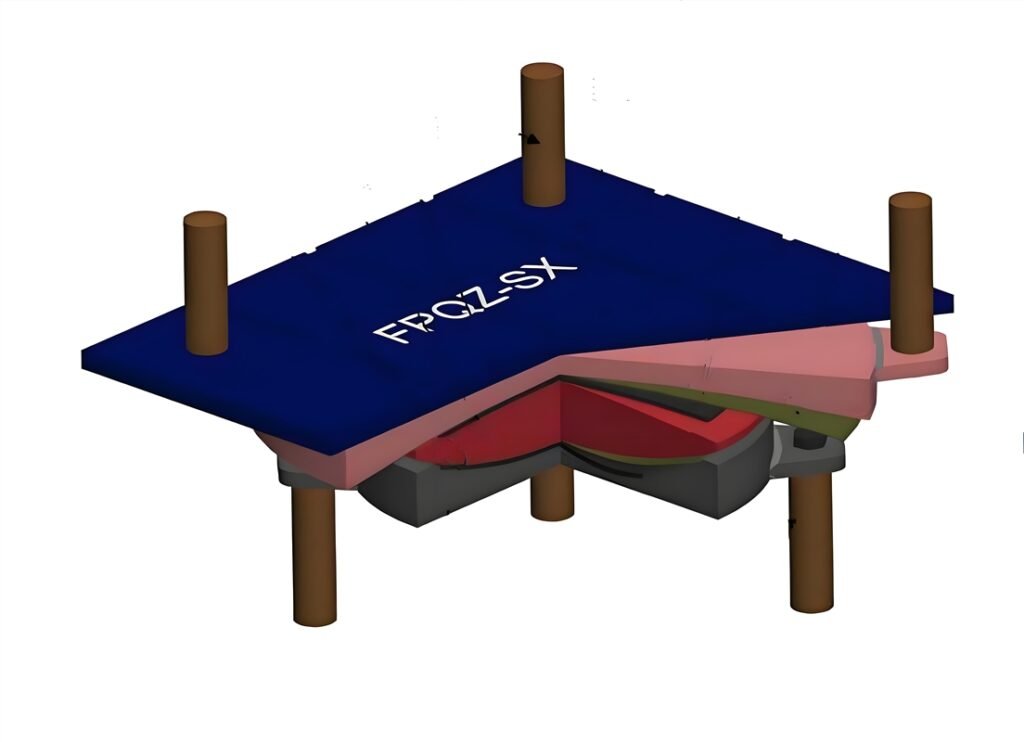

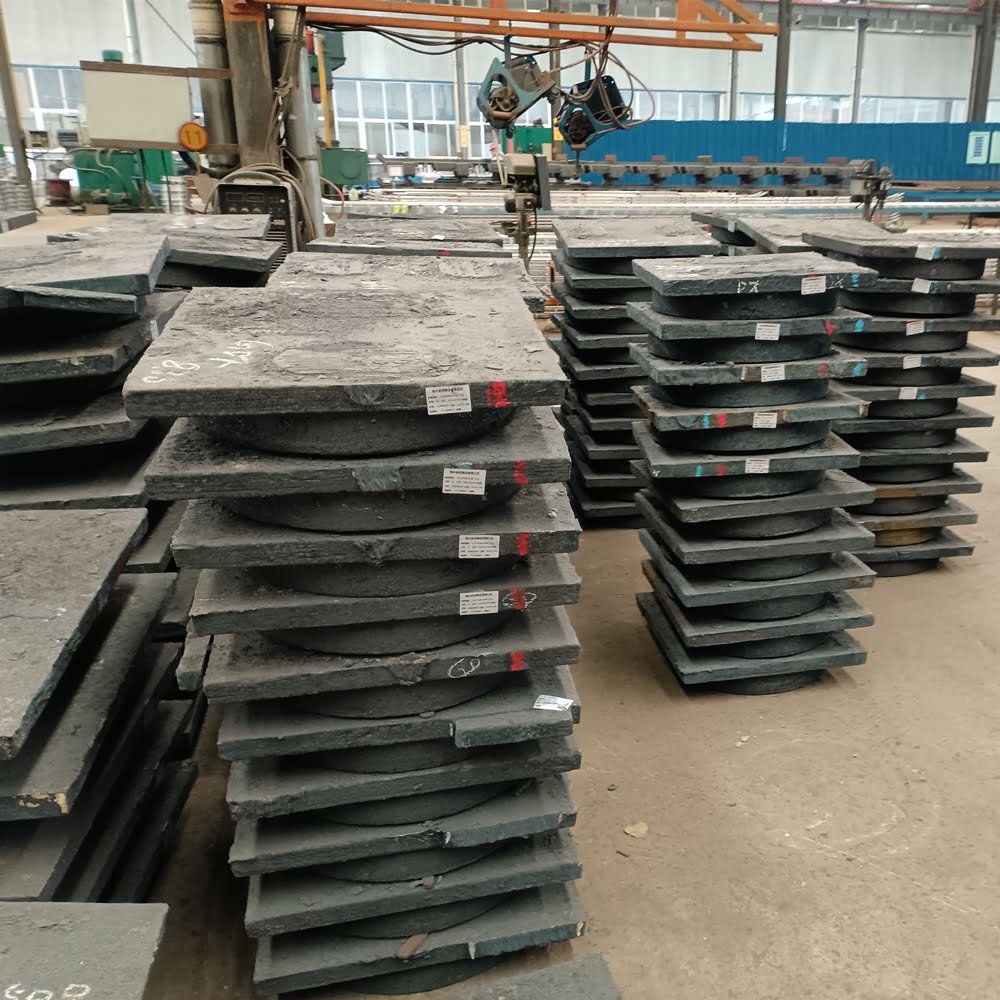

Bridge SHERICAL bearing Manufacturer

Explore our top-quality Bridge Spherical Bearings for optimal performance, durability, and seismic resistance.

Explore our top-quality Bridge Spherical Bearings for optimal performance, durability, and seismic resistance.

Spherical bearings offer reliable force transmission, flexible rotation, and adaptability to large angles. Ideal for projects with smooth rotation needs, they eliminate concerns about rubber aging, making them suitable for low-temperature applications.

Shuanglin fully complies with international standards: EN 1337 , AASHTO and China Standard.

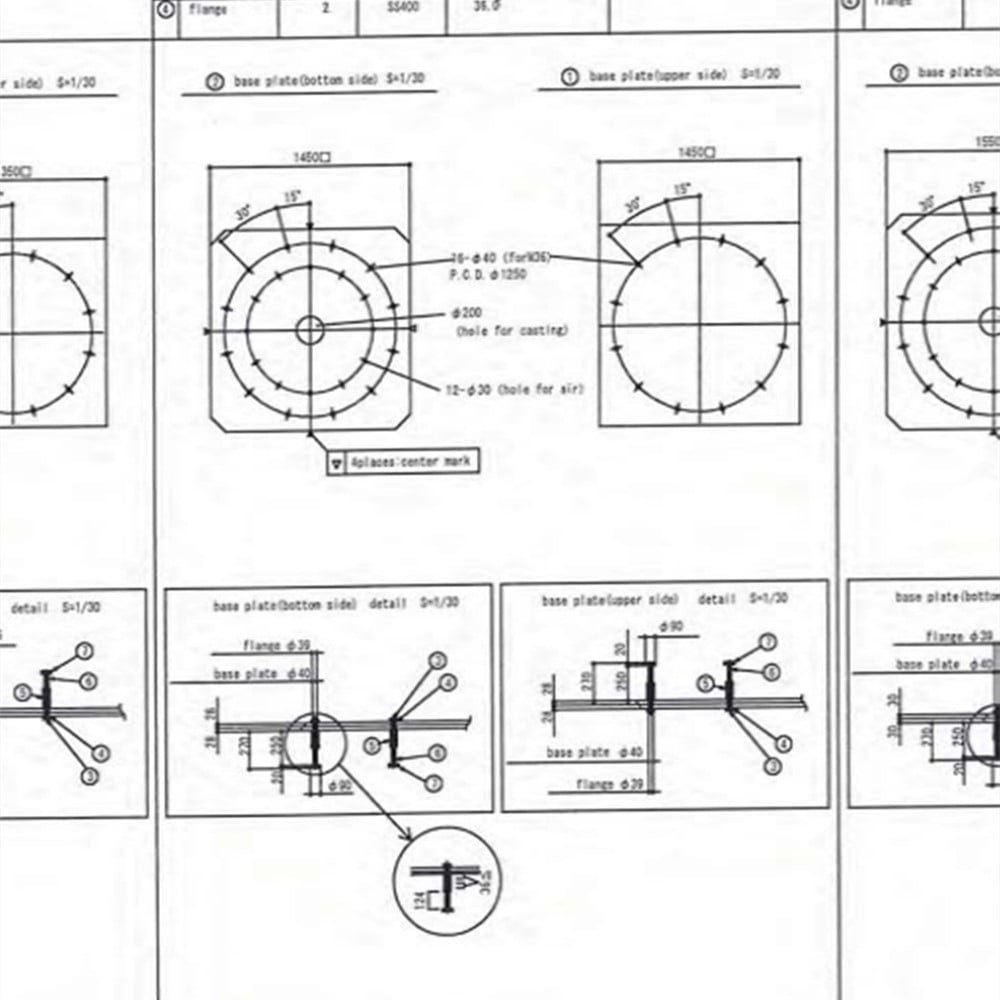

Vertical Load Capacity: From 1000kN to 20000kN

Maximum Rotation Angle: 34’~69’

Maximum Displacement:

– Longitudinal (Bridge Direction): 50~150mm

– Transverse (Perpendicular to Bridge): 20mm

Friction Coefficient: f ≤ 0.05

Horizontal Load Capacity: 10% of the vertical load capacity

Discover the distinct advantages of SHUANGLIN Bridge Spherical Bearings:

Experience the benefits of choosing SHUANGLIN for your bridge projects:

Design & Customization: Tailored design solutions to meet specific project requirements. Flexibility to customize pot bearings based on unique specifications

Production & Quality Control:Precision manufacturing processes ensuring high-quality pot bearings. Rigorous quality checks at every stage, adhering to international standards. Transportation:Efficient logistics management for safe and timely delivery. Coordination with reliable carriers to minimize transportation concerns.

After-Sales Support:Dedicated assistance for installation guidance and issue resolution. Regular follow-ups to ensure ongoing satisfaction and functionality. Technical Expertise:Access to a team of technical experts for consultation and guidance. Proactive problem-solving to address any unforeseen challenges.

Rapid development and approval of precise drawings for timely project initiation.

Use high-performance materials, simplifying production for durable bearings.

Employ cutting-edge techniques to ensure precise, reliable component production.

Apply sandblasting and rust protection, guaranteeing both performance and visual appeal.

Rigorous inspections at every stage ensure each component meets specifications.

Tailored packaging ensures safe transit, accompanied by comprehensive documentation for easy traceability, offering customers a hassle-free experience.

Under normal conditions and with proper maintenance, our bridge spherical bearings have a service life that can exceed 50 years.

Our bearings are engineered with a focus on fatigue life under dynamic loads. The rubber compound and steel reinforcement layers are optimized to provide durability and resilience under heavy loads.

We conduct a range of tests, including compression, shear, and fatigue tests, to validate the performance of our bearings. We also perform finite element analysis (FEA) and other simulations to ensure that our bearings meet the required specifications.

Yes, we offer bearings that are designed to meet specific seismic design requirements, including those specified in AASHTO, EN, and other international standards.

Please provide us with the details of your project, including the number of bearings required, the dimensions, and any specific design requirements, and we will provide a detailed quote.

Absolutely, our team of engineers is available to provide technical advice and, if necessary, on-site support to ensure proper installation and alignment of the bearings.

Our standard lead time is approximately 4-6 weeks from the order confirmation. For urgent needs, we may be able to expedite production subject to availability.

We provide a certificate of original, test reports, and detailed installation instructions with each shipment.