Pot bearing Manufacturer

At SHUANGLIN, we engineer reliability in every bridge pot bearing, elevating your projects with top-quality solutions that ensure success.

At SHUANGLIN, we engineer reliability in every bridge pot bearing, elevating your projects with top-quality solutions that ensure success.

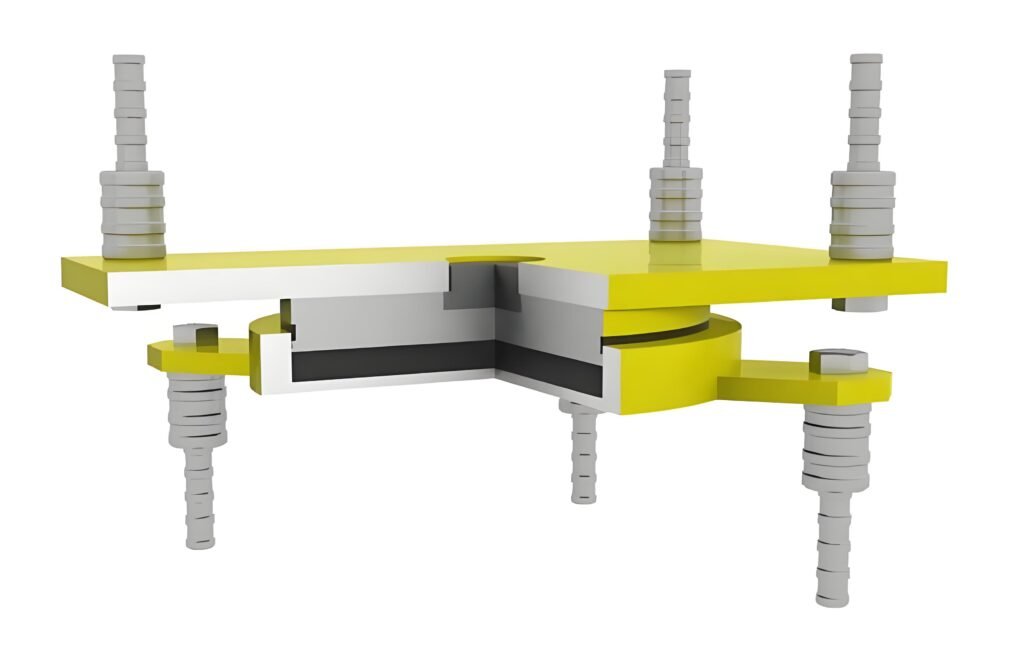

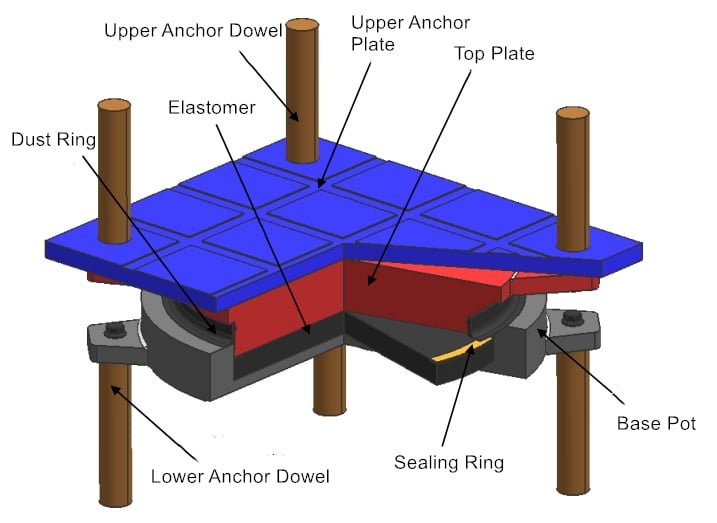

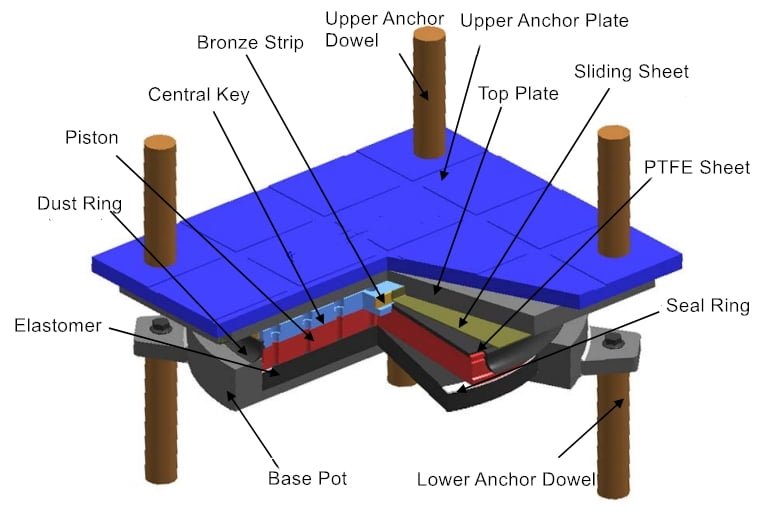

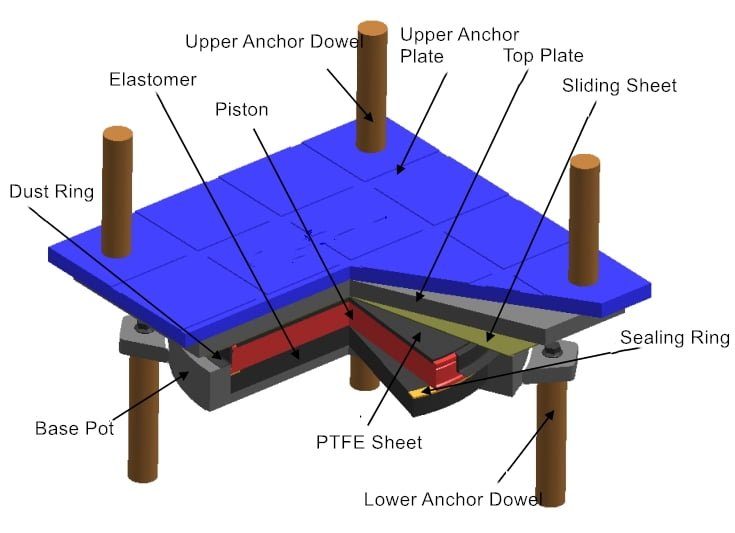

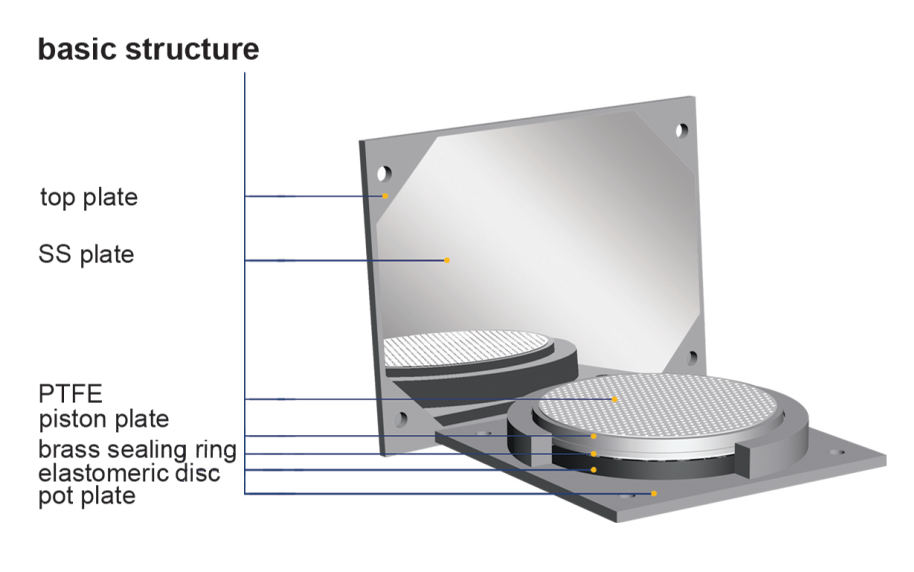

Shuanglin pot bearings handle massive vertical loads while permitting large horizontal movements and rotations. The elastomeric pad confined in steel transfers forces while allowing multi-directional flexibility.

Available in fixed, guided, or free-sliding designs for curved/skewed bridges and space constraints. Constructed to AASHTO/EN 1337 standards with high vertical stiffness, low rotational resistance, and smooth PTFE sliding surfaces.

Reliable force transfer and structural flexibility for high loads, frequent movements, or unique bridge demands. Proven solutions for your most challenging projects.

Enhance bridges with SHUANGLIN’s JPZ(II) Pot Bearing—robust, 5000ton capacity, precise load transfer, reduces stress by 30%. Ideal for durability.

Enhance bridges with SHUANGLIN’s JPZ(II) Pot Bearing—robust, 5000ton capacity, precise load transfer, reduces stress by 30%. Ideal for durability.

Material: High-strength steel (ASTM A36)

Function: Distributes loads uniformly, provides a stable surface.

Piston Plate

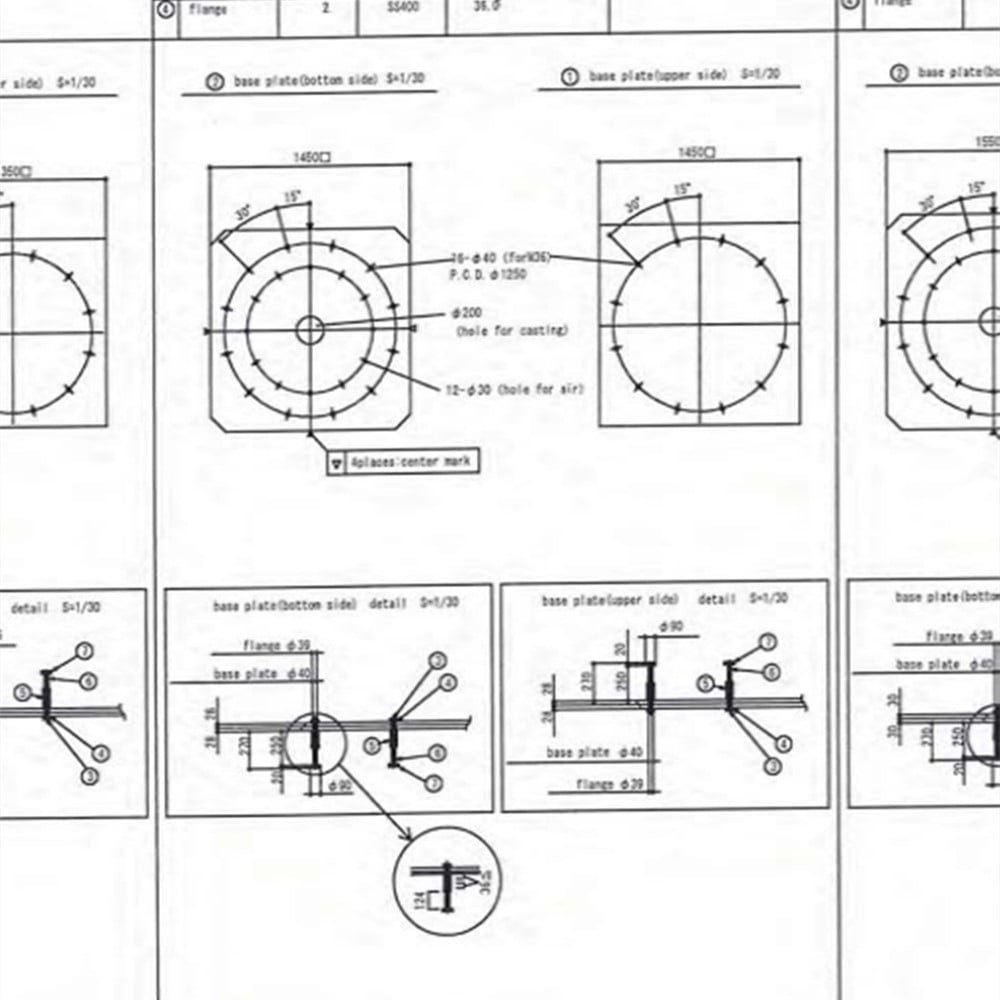

Design & Customization: Tailored design solutions to meet specific project requirements. Flexibility to customize pot bearings based on unique specifications

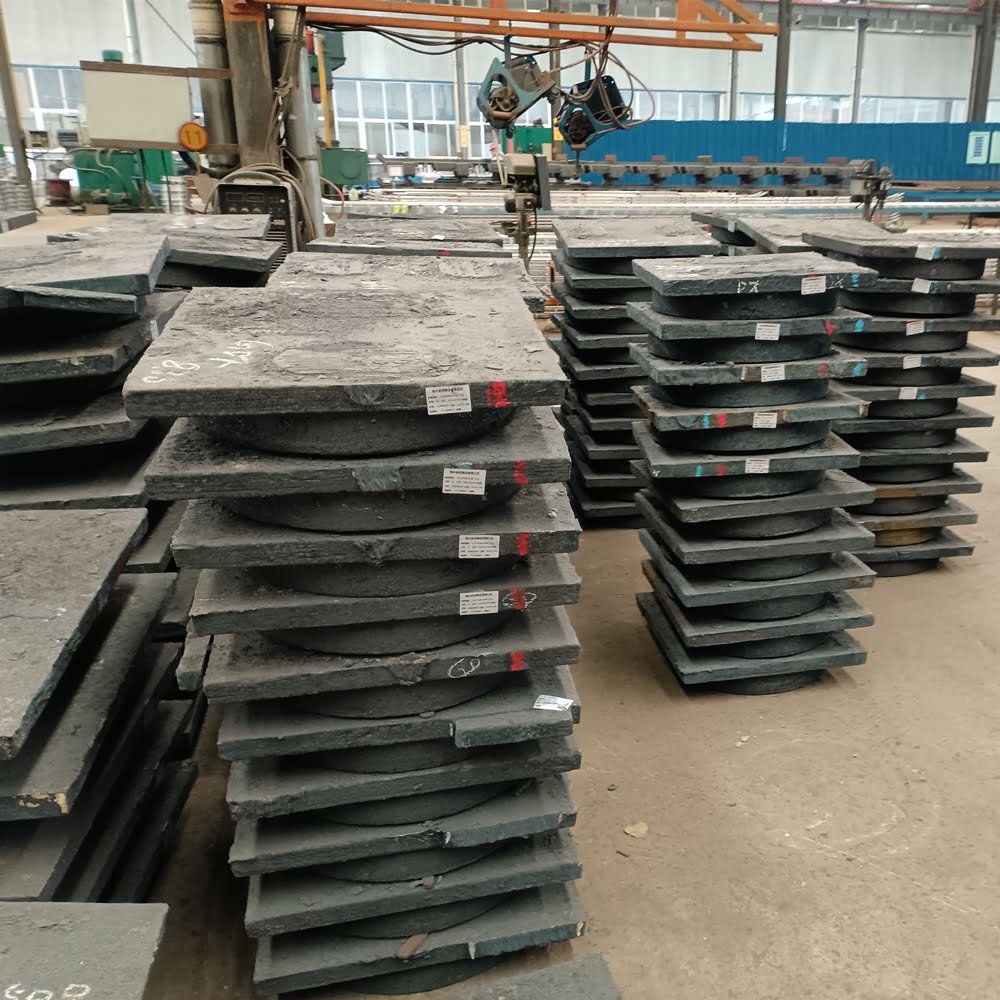

Production & Quality Control:Precision manufacturing processes ensuring high-quality pot bearings. Rigorous quality checks at every stage, adhering to international standards. Transportation:Efficient logistics management for safe and timely delivery. Coordination with reliable carriers to minimize transportation concerns.

After-Sales Support:Dedicated assistance for installation guidance and issue resolution. Regular follow-ups to ensure ongoing satisfaction and functionality. Technical Expertise:Access to a team of technical experts for consultation and guidance. Proactive problem-solving to address any unforeseen challenges.

Under normal conditions and with proper maintenance, our elastomeric bearings have a service life that can exceed 50 years.

Our bearings are engineered with a focus on fatigue life under dynamic loads. The rubber compound and steel reinforcement layers are optimized to provide durability and resilience under heavy loads.

We conduct a range of tests, including compression, shear, and fatigue tests, to validate the performance of our bearings. We also perform finite element analysis (FEA) and other simulations to ensure that our bearings meet the required specifications.

Yes, we offer bearings that are designed to meet specific seismic design requirements, including those specified in AASHTO, EN, and other international standards.

Please provide us with the details of your project, including the number of bearings required, the dimensions, and any specific design requirements, and we will provide a detailed quote.

Absolutely, our team of engineers is available to provide technical advice and, if necessary, on-site support to ensure proper installation and alignment of the bearings.

Our standard lead time is approximately 4-6 weeks from the order confirmation. For urgent needs, we may be able to expedite production subject to availability.

We provide a certificate of original, test reports, and detailed installation instructions with each shipment.