What is Bridge Expansion Joints?

Bridge expansion joints allow for movement and expansion of bridge components due to temperature changes and seismic activity. They come in various types and are made of materials like rubber, neoprene, or steel for flexibility and durability.

Bridge Expansion Joints types

Discover our diverse range, including elastomer expansion joint, finger type expansion joint, asphaltic plug joint, modular expansion joint, and strip steel expansion joints for superior bridge performance.

Comparison of various bridge expansion joints

Type | Advantages | Disadvantages | Differences | Expansion | Noise | Ease of Cleaning | Ease of Replacement | Service Life |

Elastomeric Expansion Joint | Easy to install,large lateral movements | Not suitable for high traffic volume | Made of rubber, suitable for small lateral movements | 5-50mm | Low | High | Medium | 10-20 years |

Finger Type Expansion Joint | High strength and stiffness, large lateral movements | May generate noise | Made of steel, suitable for medium lateral movements | 10-100mm | Medium | Medium | Medium | 15-25 years |

Asphaltic Joint Plug | Easy to install, large lateral movements | Not suitable for high traffic volume | Made of asphalt, suitable for small lateral movements | 5-50mm | Low | High | Medium | 10-20 years |

Strip Steel Expansion Joint | High strength and stiffness, large lateral movements | May generate noise | Made of steel, suitable for medium lateral movements | 10-100mm | High | Low | Medium | 20-30 years |

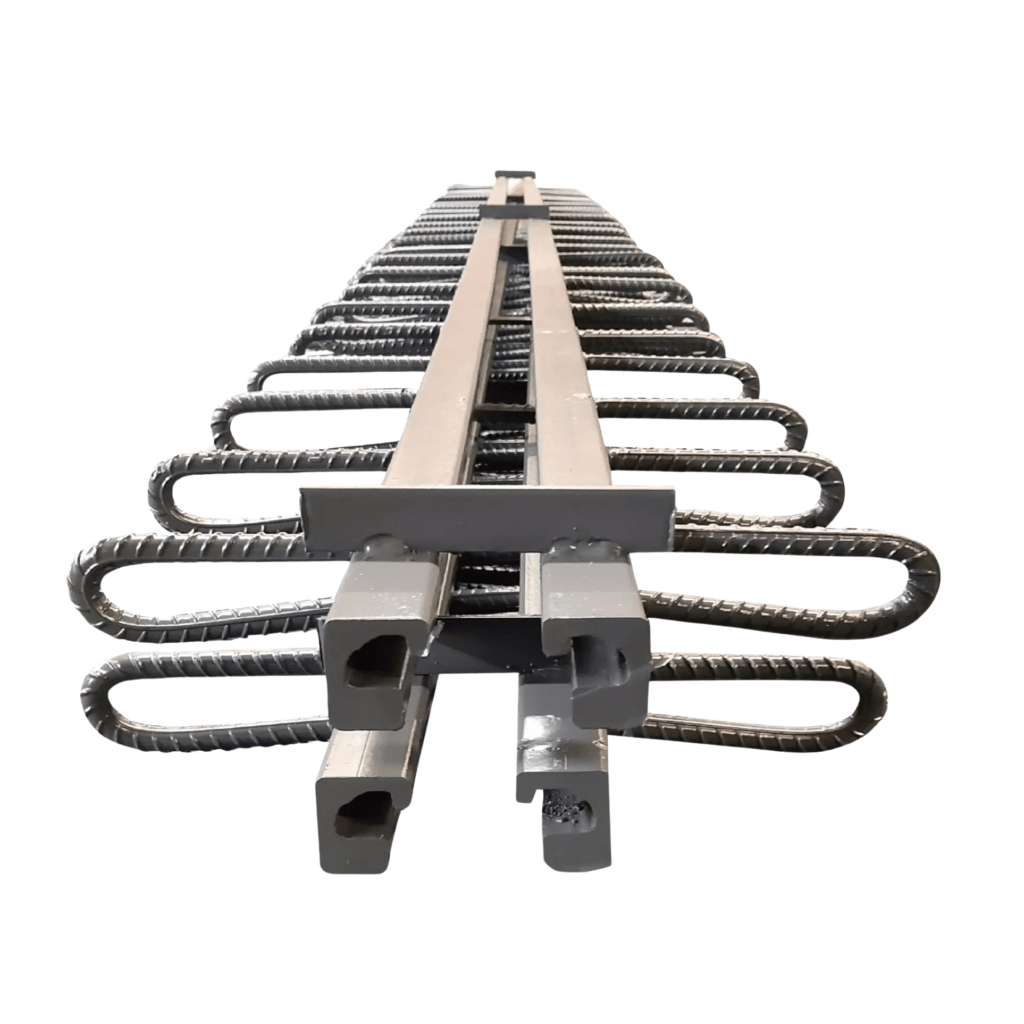

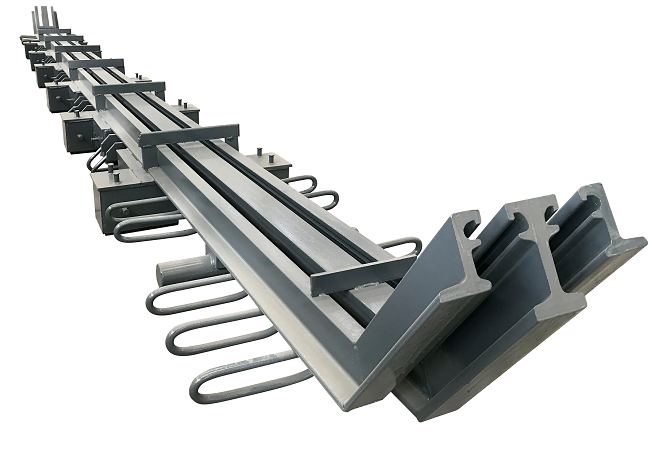

Modular Expansion Joint | Absorb large lateral movements and withstand high loads | Expensive | Made of rubber and steel, suitable for large lateral movements | 50-500mm | Low | High | High | 25-35 years |

Why are bridge expansion joints important?

- Expansion joints prevent bridge damage from temperature and seismic changes.

- They reduce stress, extending the bridge’s lifespan.

- Joints ensure a smooth, safe driving surface for vehicles.

Why Choose Us?

Elevate Your Projects with Shuanglin’s Bridge Expansion Joints

★ Versatility in producing various brand models.★ Expert design services with detailed drawings.

★ ASTM-compliant production for materials and manufacturing.

★ Precision craftsmanship and impeccable surface finishes.

★ Cost-efficient options to help clients save.

OUR SERVICES

Your Gateway to Quality Expansion Joints.

Initial Consultation

Connect with our experts for tailored expansion joints. Let's craft success together!

Production Excellence

Elevate your project with SHUANGLIN's customization magic. Our high-tech production ensures masterful, resilient expansion joints.

Negotiation and Pricing

Budget brilliance! Navigate negotiation for quality without breaking the bank.

Long-Term Partnership

Beyond a sale, it's a legacy. Seal the deal, benefit from ongoing support, and tested assurance for project triumph!

Installation and Maintenance

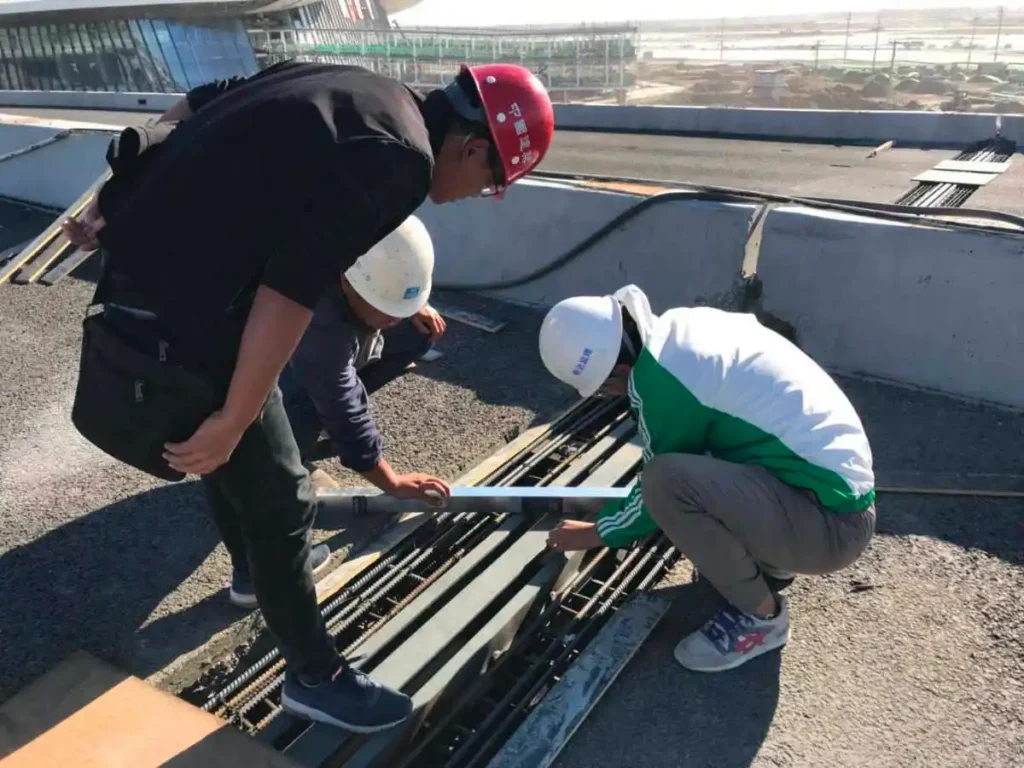

# Best practices for installing bridge expansion joints

- Detailed Planning:

Thoroughly plan the project by understanding bridge design, load requirements, and expansion joint specifications. - Accurate Measurement:

Conduct precise measurements and surveys to align expansion joint dimensions with design requirements. - Material Selection:

Choose materials based on environmental conditions, loads, and climate, ensuring durability and resistance. - Correct Installation:

Follow manufacturer guidelines for secure and proper integration of the expansion joint into the bridge structure. - Temperature and Load Consideration:

Account for temperature changes and load fluctuations during installation. - Regular Inspection:

Conduct regular inspections to check sealing, material condition, and connection points for prompt issue identification. - Operator Training:

Ensure operators undergo training on expansion joint characteristics, maintenance, and emergency procedures for reliable operation.

# Maintenance bridge expansion joints

- Regular Inspections:

Conduct quarterly inspections to assess wear and tear, ensuring the expansion joints remain within acceptable limits. - Biannual Cleaning:

Implement cleaning procedures twice a year to remove debris, dirt, and corrosive materials, maintaining a cleanliness level of at least 95%. - Sealant Maintenance:

Inspect and replace sealants annually, ensuring a tight seal with a maximum allowable water ingress of 5 milliliters per linear meter. - Functional Testing:

Perform movement and functionality tests every six months to verify the expansion joint’s capacity to accommodate a minimum of 25% of the expected bridge movements. - Structural Repairs:

Address identified issues promptly, with a goal to complete repairs within 30 days of detection, including the replacement of worn parts and addressing structural concerns.

# Repair and Replacement

- Preparation:

- Assess project scope, considering design, traffic, and materials.

- Develop a detailed plan, including timeline, budget, and safety protocols.

- Inspect and prepare the bridge surface, addressing any irregularities or corrosion.

- Replacement:

- Safely dismantle the existing joint, preserving surrounding structures.

- Follow manufacturer guidelines for precise alignment, attachment, and sealing.

- Apply suitable sealants to prevent water ingress, meeting specified tolerances.

- Inspection:

- Conduct regular quality control inspections throughout the replacement process.

- Address any deviations promptly to ensure compliance with safety and design standards.

- Document lessons learned for future reference and improvements.

Simplify Your Procurement Process

With our comprehensive solutions, we aim to make every stage of your bridge bearing procurement hassle-free and assure you peace of mind.

1. Consultation Phase

In the initial phase, our focus is on understanding and meeting your specific project requirements of bridge expansion joint, confirm details of drawings.

- Accommodate Existing Drawings: Review and discuss your drawings, ensuring precise alignment with your specifications.

- Custom Design Support: If you lack drawings, our experts can design them or offer valuable suggestions based on your project needs.

2. Quotation and Customization

Transparent Quoting Process:Our commitment is to provide a clear and straightforward quoting process.

Customization Options:Tailored to your specifications, our offerings ensure personalized solutions for your unique requirements.

3. Quality Assurance

Control Excellence: Our dedication to reliability begins with rigorous quality controls.

Beyond Standards: Our testing protocols surpass industry norms, ensuring exceptional product performance

4. Timely Delivery and Support

Streamlined Logistics: Seamless international trade processes for smooth logistics and documentation support.

After-Sales Dedication: Depend on our team for dedicated assistance beyond your initial procurement.

FAQ

Our joints excel in durability and resilience, surpassing international standards with rigorous testing.

SHUANGLIN’s expert team guides you. Share project details; we recommend a suitable, tailored joint.

Absolutely. We customize joints to seamlessly integrate into your construction plans. Share project details for a tailored solution.

Certainly. We have a portfolio of successful projects and can provide references or case studies upon request.

Yes, we offer on-site training and technical assistance to ensure proper installation and optimal performance of our expansion joints.

Beyond the sale, we offer transparent communication, technical support, and warranties, ensuring lasting project success.

Shuanglin warmly embraces you with responsive support, comprehensive warranties, and expert guidance. Our commitment ensures not only enduring performance but also client satisfaction, making your journey with us seamless and successful.