Leading Asphaltic Joint Plug Manufacturer

Innovation, Quality, and Performance – Elevate Your Projects with Our Superior Manufacturing

Innovation, Quality, and Performance – Elevate Your Projects with Our Superior Manufacturing

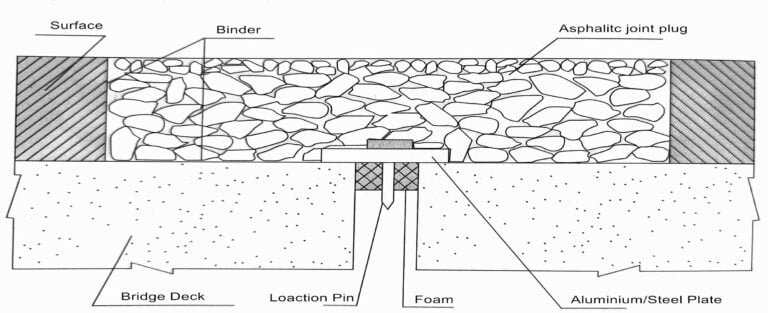

Asphaltic plug joint (APJ) is a type of asphalt-filled bridge expansion joint, it is ideal for small to medium-span bridges. For spans with 20mm-40mm expansion. It involves melting asphalitc joint plug, pouring it into heated crushed stones, forming the joint. Crushed stones support loads, and it meets expansion requirements at 25°C to 60°C.

Maintains integrity in diverse temperatures, resisting softening or cracking.

Ensures robust bonding to bridge structures, accommodating movements.

Competitive pricing with superior quality compared to European and American brands.

Seamlessly integrates joints with minimal noise during movement.

It is suitable for highway bridges, urban overpasses, and viaducts with an expansion range below 50mm, designed for regions with temperatures ranging from -25°C to 60°C.

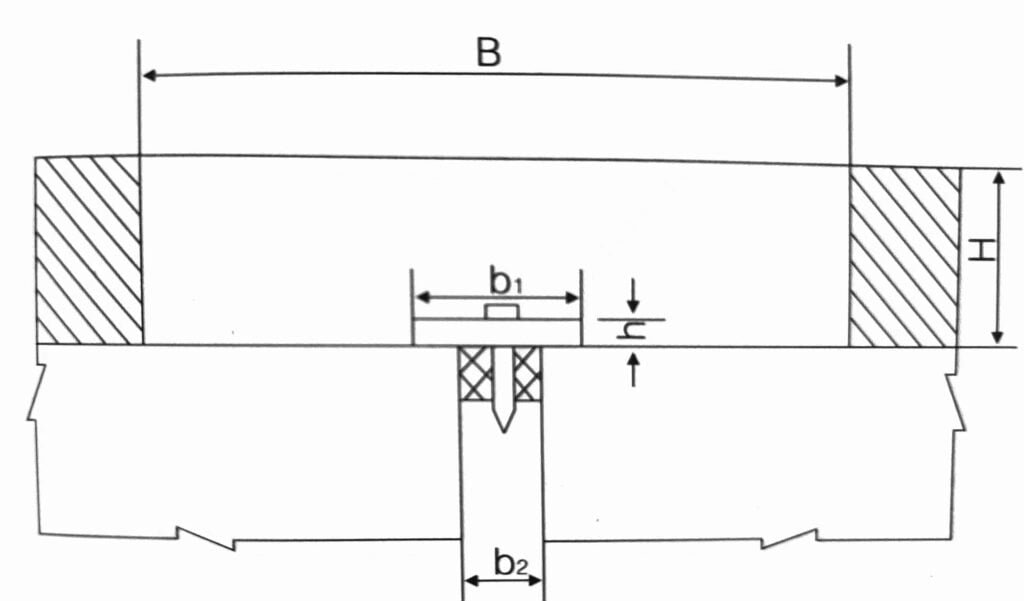

| Movement △B | Slot width B | Slot depth H | Gap b2 | Steel plate b1xh |

|---|---|---|---|---|

| 10 | 200 | 60 | 20 | 120×6 |

| 20 | 300 | 60 | 20 | 140×6 |

| 30 | 400 | 60 | 30 | 160×6 |

| 40 | 500 | 60 | 40 | 180×6 |

| 45 | 600 | 60 | 40 | 200×6 |

| 50 | 700 | 60 | 40 | 220×6 |

| Movimiento(mm) | Brecha LxH (mm) | Cantidad por metro lineal | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cubierta de acero (mm) | Piedra(m2) | APJ (kg) | Adhesivo (kg) | Placa de espuma (pcs) | Clavos(pcs) | Ancla (m) | Perno de expansión (pcs) | ||

| 10 | 200×60 | 120×6 | 0.012 | 7.92 | 0.10 | 1000 | 4 | 2 | 8 |

| 20 | 300×60 | 140×6 | 0.018 | 11.88 | 0.13 | 1000 | 4 | 2 | 8 |

| 30 | 400×60 | 160×6 | 0.032 | 21.12 | 0.17 | 1000 | 4 | 2 | 8 |

| 40 | 500×60 | 180×6 | 0.040 | 26.40 | 0.20 | 1000 | 4 | 2 | 8 |

| 45 | 600×60 | 220×6 | 0.048 | 31.68 | 0.23 | 1000 | 4 | 2 | 8 |

| 50 | 700×60 | 220×6 | 0.056 | 36.96 | 0.26 | 1000 | 4 | 2 | 8 |

The modified elastomeric binder shall meet or exceed the requirements of ASTM-3405 and ASTM-1190.

| PROPERTIES | STANDARD | REQUIREMENTS |

|---|---|---|

| Softening point, min | ASTM D36 | 100℃ |

| Tensile adhesion, min. | ASTM D5329 | 700% |

| Ductility min. at 25°C | ASTM D113 | 400mm |

| Penetration, max. at 25°C 150g, 5s | ASTM D5329 | 75mm |

| Low temperature penetration, min. at -18°C 200g, 60s | 9.1 | 1.0mm |

| Flow, max. 5h at 60°C | ASTM D5329 | 3.0mm |

| Resiliency, min. – max. at 25°C | ASTM D5329 | 40-60% |

| Asphalt compatibility | ASTM D5329 | Pass |

| Recommended application heating temperature range | ASTM D5329 | 180℃-230℃ |

| Bond 3 Cycles at -7°C 100% Elongation | ASTM D405 | Pass |

| Flexibility, at -23°C | ASTM D5329 | Pass |

1. Cut, groove, and clean the slot according to the design dimensions.

2. Backfill the slot with steel fiber concrete, compact, and level it.

3. After concrete strength reaches 70% of the design strength, embed anchor screws in drilled holes at 250mm intervals. Install a longitudinal connecting steel bar and fit the joint cover plates.

4. Thoroughly clean the slot of sand, debris, and dust. Dry the slot.

5. Ensure complete dryness in the slot area, cover both sides of the pavement with isolation film, and uniformly apply Asphaltic Joint Plug-specific adhesive to the slot’s bottom and sides.

6. Clean and heat stones, preferably using a flame jet in a stone heating machine, at a temperature of 130°C to 150°C.

7. Heat the Asphaltic Joint Plug-specific adhesive to a temperature of 190°C to 210°C, quickly mix it in the correct proportion, and pour it into the heated and dried stones, stirring evenly.

8. Quickly place the heated and stirred Asphaltic Joint Plug crushed stone adhesive in the slot and immediately flatten it with a special milling plate.

9. After flattening, evenly spray a layer of Asphaltic Joint Plug-specific bonding solution on the surface of the crushed stone, quickly scrape it flat, meeting smoothness requirements.

10. Clean the construction site and close traffic.