Finger Bridge Expansion Joint Manufacturer

Unmatched in elastomeric bridge bearings, we’ve played a key role in over a thousand global projects. Trust SHUANGLIN for reliability, precision, and proven excellence!

Unmatched in elastomeric bridge bearings, we’ve played a key role in over a thousand global projects. Trust SHUANGLIN for reliability, precision, and proven excellence!

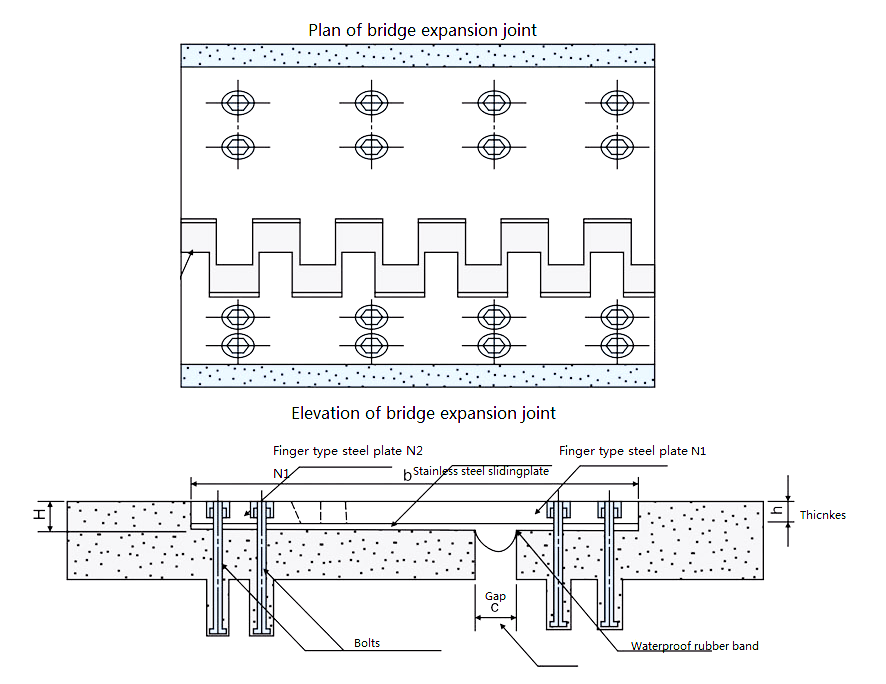

Finger expansion joint facilitates movement and expansion between adjacent structures in construction. It accommodates material shifts caused by temperature changes or settling while ensuring a continuous watertight seal. The term “finger” denotes interlocking ribs that flex, commonly employed in buildings and bridges to prevent damage and preserve structural integrity.

Boasting advanced design for superior bridge integration, our joints ensure optimal functionality and durability.

Utilizing high-quality raw materials rigorously tested to meet international standards, we guarantee longevity and resilience.

With state-of-the-art facilities and strict quality controls, each joint meets and exceeds industry standards.

Benefit from our dedicated team's guidance and expertise, ensuring seamless integration and optimal performance.

| Model | C | h | Anchor & Nut | b | H | Installing ground height |

|---|---|---|---|---|---|---|

| 80 | 80 | 28 | M18 x 180 | 740 | 33 | 120 |

| 100 | 100 | 28 | M18 x 180 | 800 | 33 | 120 |

| 120 | 120 | 30 | M18 x 180 | 860 | 35 | 120 |

| 140 | 140 | 30 | M18 x 180 | 920 | 35 | 120 |

| 160 | 160 | 30 | M18 x 180 | 980 | 35 | 120 |

| 180 | 180 | 32 | M20 x 200 | 1080 | 37 | 120 |

| 200 | 200 | 32 | M20 x 200 | 1140 | 37 | 150 |

| 220 | 220 | 32 | M20 x 200 | 1200 | 37 | 150 |

| 240 | 240 | 34 | M22 x 220 | 1260 | 39 | 150 |

| 260 | 260 | 34 | M22 x 220 | 1320 | 39 | 150 |

| 280 | 280 | 34 | M22 x 220 | 1380 | 39 | 150 |

| 300 | 300 | 36 | M24 x 240 | 1480 | 41 | 150 |

| 320 | 320 | 36 | M24 x 240 | 1540 | 41 | 150 |

| 340 | 340 | 38 | M24 x 240 | 1600 | 43 | 150 |

| 360 | 360 | 38 | M24 x 240 | 1660 | 43 | 150 |

To guarantee the quality of Finger expansion joints, we follow these professional steps:

Adhere to precise manufacturing processes. Employ advanced machinery and technology to create expansion joints with accurate specifications, meeting the required standards.

Implement stringent quality control measures at every stage of production. Regularly inspect and test the expansion joints to identify and rectify any potential issues promptly.

Ensure that the manufacturing process complies with industry and international standards.

Emphasizing secure packaging, each product is carefully wrapped, reinforcing our dedication to delivering flawless elastomeric bearing pads.