Building Isolation

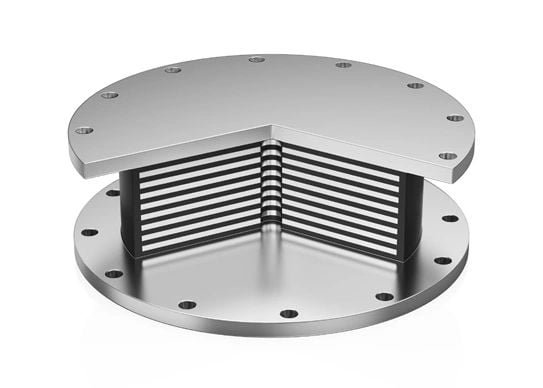

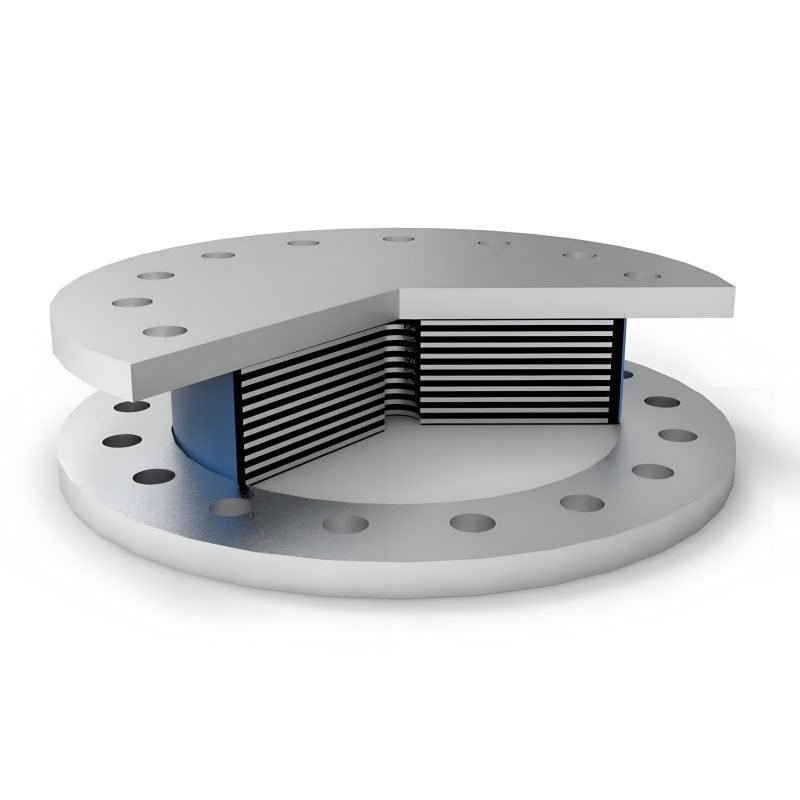

Building Seismic isolation works by decoupling the building from the ground, absorbing and dissipating seismic energy, and minimizing the transfer of ground vibrations to the building, thus reducing potential damage during seismic events. They are made of materials like natural rubber and composite rubber, providing high damping properties and stable recovery capabilities

As the leading manufacturer, Shuanglin ensure direct production control and quality assurance, providing reliable and stable products.

☰ Types of Seismic Isolation Bearings

There are three basic types of seismic isolation bearings: Elastomeric Rubber Bearings, Lead Rubber Bearings and High Damping Rubber Bearings.

- Damping Coefficient: Less than 5%

- Material: Typically made of natural rubber or other elastomeric materials

- Deformation Capacity: Can accommodate large horizontal displacements during earthquakes

- Shear Modulus: Specific values may vary based on the manufacturer and the intended use

- Damping Coefficient: Up to 30%

- Shear Modulus: 0.8 MPa, 1.0 MPa, 1.2 MPa

- Working Temperature Range: -25 °C to +60 °C

- Lead Core Quantity: Single or multiple

- Shape: Rectangular and round

- Lead core quantity: Single or multiple

Generally, a separate damper is not required, making it an excellent choice for areas with space constraints. From light column loads until high rise building can be accommodated.

- Damping Coefficient: 10% to 18%

- Material: Typically made of natural rubber

- Deformation Capacity: Can accommodate large horizontal displacements during earthquakes

- Shear Modulus: 0.8 MPa, 1.0 MPa, 1.2 MPa

- Working Temperature Range: -25 °C to +60 °C

Difference between Seismic Isolations

| Characteristic | Elastomeric Rubber Bearings | Lead Rubber Bearings | High Damping Rubber Bearings |

|---|---|---|---|

| Material | Low-damping natural or synthetic rubber, high-damping natural rubber, or lead-rubber | Laminated elastomeric bearing pads, top and bottom sealing & connecting plates, and a lead plug inserted in the middle of the bearing | High damping rubber material, with a layer of steel in the middle, and a lead-free plug |

| Damping Ratio | <5% | >15% | 10-18% |

| Seismic Function | Minimizes transfer of ground vibrations | Reduces accelerated speed and uniformly changes large displacement | Produces large deformation and small stiffness, with excellent seismic effect |

| Lead Plug | N/A | Inserted in the middle of the bearing, slides with the laminated rubber during earthquakes, converting the energy of movement into a slow vibration of the building | N/A |

| Rubber | Various types of rubber | Generally made of natural rubber, which is more flexible than elastomeric bearing pads | High damping rubber material |

| Horizontal Stiffness | Moderate | High | Moderate |

| Vertical Load Capacity | Moderate | Moderate | Moderate |

| Horizontal Movement | Large | Large | Large |

| Shear Deformation | Moderate | High | Moderate |

| Suitability | General | Moderate | Moderate |

How do seismic isolators work

Seismic isolators work by decoupling a structure from the ground, thereby minimizing the earthquake forces acting on the building. They consist of various components such as lead rubber bearings, oil dampers, and sliding units, which are intended to provide flexibility and absorb the energy generated by the movement of the structure. The isolators can be placed in the basement storey, above the basement storey, or on the foundation level, and they are designed to dissipate the input energy of an earthquake, preventing damage to the structure. Seismic isolators can be of two types: base isolation, where isolators are installed at the base of the structure, and mid-story isolation, where isolators are installed at a higher level in the building. The application of seismic isolation has increased significantly, with the number of seismic isolated buildings exceeding 4000.

what are the benefits of using seismic isolators in construction?

- Enhanced Safety: Minimizes structural damage during earthquakes, prioritizing safety.

- Cost-Effective Solution: Reduces long-term maintenance costs for economic efficiency.

- Structural Longevity: Prolongs the lifespan of buildings and bridges by mitigating seismic impact.

- Adaptable Design: Versatile integration suitable for various structures.

- Compliance Assurance: Ensures adherence to seismic safety standards for regulatory compliance.

Compare to other earthquake protection systems

Internation Standards

- ISO 22762:2017 – Base isolators – General principles on design

- AASHTO Guide Specifications for LRFD Seismic Bridge Design (LRFD Guide Specifications)

- ASCE/SEI 7-16 – Minimum Design Loads and Associated Criteria for Buildings and Other Structures

- EN 15129:2009 – Devices for the Seismic Isolation of Buildings – Test Methods

- GB/T 20688.3-2006-Elastomeric seismic-protection isolators for buildings.

How to evaluate the quality and performance of Seismic Isolators?

- Design analysis: Perform preliminary analysis to determine the target period, target displacement, axial capacities, and the types of isolator units. Perform seismic analysis for design-based (DBE) and maximum-considered earthquake (MCE) cases.

- Material selection: Choose the appropriate isolator type for the project requirements, such as elastomeric rubber bearings, elastomeric lead-rubber bearings, friction-based isolators, and friction pendulum systems.

- Manufacturing and quality control: Test isolators during prototype and production to verify design parameters and ensure performance and quality.

- Installation: Install isolators correctly and ensure they are in good contact with other parts of the structure.

- Performance testing: Test the structure’s performance to ensure the isolators’ effectiveness. This can include measuring compression, acceleration, and shaking.

- Disaster simulation: Simulate disasters to evaluate isolator performance during earthquakes and ensure they can reduce the structure’s seismic impact.

Why Choose Us

Experience and Expertise:

With over 10 years of experience in seismic isolation bearing manufacturing, our team boasts 10+ years of industry know-how, having completed 200+ successful projects.

Outstanding Product Performance

Tested to withstand over 5000 tons and offering a 25-year lifespan, we can produce a full series of seismic rubber isolators. Our bearings ensure reliable protection in any condition.

Certifications and Testing

ISO 9001 certified, our products meet international standards and undergo rigorous testing for quality assurance.

Strong Production Capacity and Delivery

With a monthly capacity of 10,000+ units, we deliver orders within 3-4 weeks, ensuring project timelines are met.

Installation and Maintenance

HONGRUI can provide online installation guidance services. Proper installation and meticulous maintenance of seismic isolation systems transform buildings into fortresses against the seismic fury of earthquakes. By following these comprehensive guidelines, building owners and managers can safeguard their structures, ensure the safety of their occupants, and protect their investments from the devastating effects of earthquakes.

# Seismic Isolation Installation: A Step-by-Step Journey

- Site Preparation: Prepare the foundation area to ensure a level and stable base for the seismic isolators.

- Seismic Isolator Installation:Carefully position and secure the seismic isolators according to the design drawings.

- Jacking and Leveling:Precisely raise and level the building using a jacking system to achieve a perfectly level structure.

- Utility Connection:Relocate and connect utilities with flexible connections to accommodate the isolators and the new building height.

- Temporary Support Removal:Carefully remove temporary supports in a prescribed sequence to ensure the building’s stability.

# Seismic Isolation Maintenance: Vigilance for Enduring Protection

- Regular Visual Inspections:Conduct thorough visual inspections annually to detect any signs of damage or deterioration on the seismic isolators.

- Performance Testing and Evaluation:Perform periodic testing to verify the performance characteristics and load-bearing capacity of the seismic isolators.

- Cleaning and Protection:Regularly clean and protect the seismic isolators from harsh environmental conditions to maintain their integrity.

- Prompt Repairs and Replacements:Address any damage or defects promptly, and replace faulty isolators with new ones of the same type and specifications.

Simplify Your Procurement Process

Choose us as your trusted partner for building isolators and ensure the success of your project.

1. Unparalleled Technical Expertise

2. Efficient Production and Timely Delivery

- Streamlined contract process for smooth transition

- Robust manufacturing capabilities for timely fulfillment

- Prompt delivery and logistics for expedited arrival

3. Rigorous Testing and Quality Assurance

- Comprehensive in-house testing for quality assurance

- 100% success rate in third-party type testing

- Stringent quality control procedures for industry-leading standards

4. Expedited Shipping and Complete Documentation

- Logistics expertise for efficient shipping solutions

- Complete documentation, including packing lists and certificate

- Seamless customs clearance for hassle-free import

FAQ

Our joints excel in durability and resilience, surpassing international standards with rigorous testing.

SHUANGLIN’s expert team guides you. Share project details; we recommend a suitable, tailored joint.

Absolutely. We customize joints to seamlessly integrate into your construction plans. Share project details for a tailored solution.

Certainly. We have a portfolio of successful projects and can provide references or case studies upon request.

Yes, we offer on-site training and technical assistance to ensure proper installation and optimal performance of our expansion joints.

Beyond the sale, we offer transparent communication, technical support, and warranties, ensuring lasting project success.

Shuanglin warmly embraces you with responsive support, comprehensive warranties, and expert guidance. Our commitment ensures not only enduring performance but also client satisfaction, making your journey with us seamless and successful.

Send your Inquiry

We will reply within 12hours.