QUALITY CONTROL

Standard

Our production and testing standards comply with international standards such as EN 1337 in Europe, AASHTO in USA, JSCE or JIS in Japan or others.

Bridge Bearings

EN 1751 - European Standard

AASHTO LRFD Bridge Design Specifications - United States

BS EN 13677 - British Standard

JIS B 8817 - Japanese Industrial Standard

ISO 19651 - International Standard

Bridge Expansion Joints

EN 1337 - European Standard

AASHTO LRFD Bridge Design Specifications - United States

BS EN 1337 - British Standard

JSCE Guidelines - Japan

ISO 22762 - International Standard

Building seismic isolation

EN 15129 - European Standard

AISC 358 - United States

ASCE 7 - United States

AISC 358 - Seismic Isolation Structures for Buildings

ISO 22762 - International Standard

GB 50183-2018 - Code for Seismic Design of Buildings

Testing Items

Our factory laboratory is capable of completing all testing projects.

Bridge Bearings

- Rubber property: Hardness, Tensile Strength, Elongation, Abrasion Resistance, Aging resistance, etc

- Bearing Property: Vertical Loading, Horizontal Shear, Rotation, Stiffness, Friction, Chemical Resistance

Bridge Expansion Joints

- Rubber property: Hardness, Tensile Strength, Elongation, Abrasion Resistance, Aging resistance, etc

- Steel plate: Dimension, Weld Inspection,Corrosion:Mill Certification, Ultrasonic Testing

- Expansion joint Property: Movement Capability, Load-Carrying Capacity, Sealing Performance

Building seismic isolation

- Rubber property: Hardness, Tensile Strength, Elongation, Abrasion Resistance, Aging resistance, etc

- Bearing Property: Vertical Loading, Horizontal Loading, Displacement Capability, Rotation, Damping, Restoring Force, Residual Displacement, Temperature and Environmental Resistance, Bond Strength

Quality Assurance

At Shuanglin company, Quality is the heart of what we do. From meticulous raw material selection to precision manufacturing, we ensure excellence at every stage.

1. Material Inspection

We begin by rigorously inspecting steel plates, rubber, and other raw materials. Only those meeting our stringent criteria proceed to the next stage.

2. Rubber Specimen Testing

We create rubber samples, subjecting them to rigorous tests. Only when they meet our standards are they blended into the final rubber material.

3. Production Inspection

Throughout production, our products undergo size and appearance checks to guarantee a flawless finish. We leave no room for imperfections.

4. Continuous Sampling

We conduct random sampling during production. If any issues arise, immediate corrections are made, ensuring consistency in quality.

5. Final Product Testing

After production, we perform thorough sampling on the final batch. Each product is meticulously examined, and inspection reports are generated.

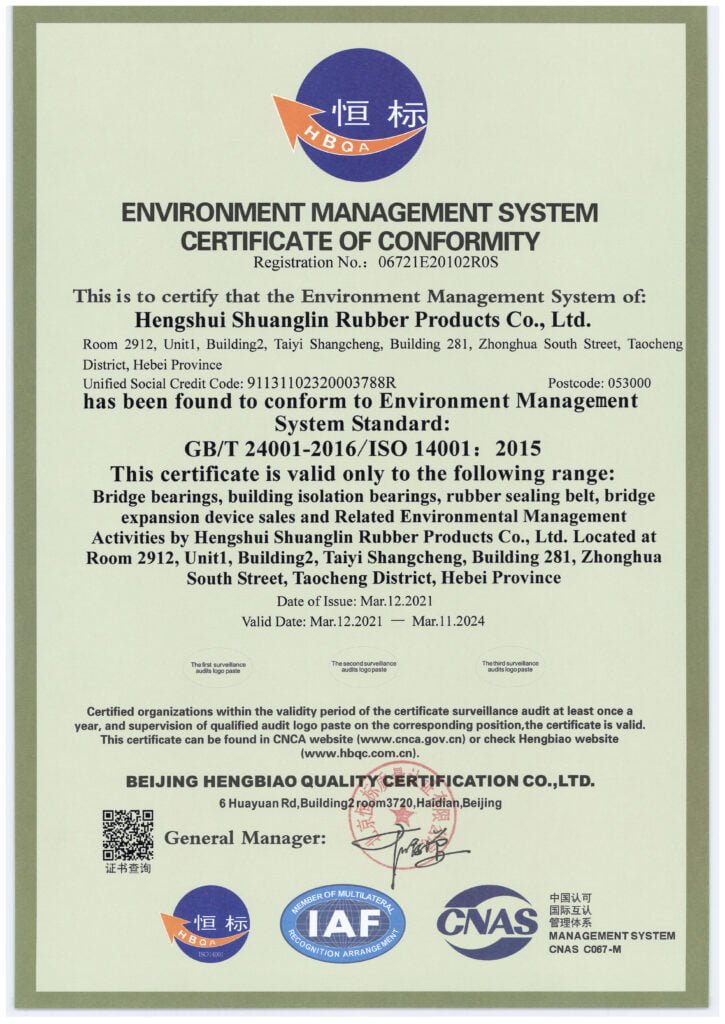

CERTIFICATION

ISO 9001:2015

ISO 14001

ISO 45001:2018